Introduction: The Backbone of Global Cleaning Technology

China has established itself as the world's manufacturing hub for cleaning appliances, with a supply chain ecosystem that seamlessly integrates advanced production capabilities, innovative technologies, and efficient logistics networks. The country's cleaning appliance supply chain represents a sophisticated web of manufacturers, component suppliers, distributors, and service providers that collectively enable the production and global distribution of everything from industrial scrubbers to smart home cleaning devices.

The evolution of China's cleaning appliance supply chain has been remarkable. From basic manufacturing capabilities two decades ago, the ecosystem has matured into a technology-driven network characterized by vertical integration, digital management, and sustainable practices. This transformation has positioned Chinese suppliers as critical partners for global brands seeking quality, reliability, and innovation in the highly competitive cleaning appliance market.

In this comprehensive analysis, we explore the top supply chains powering China's cleaning appliance industry. We'll examine the key players, their strategic advantages, and what makes each supply chain unique in this dynamic landscape.

1. LINCINCO: The Integrated Smart Cleaning Solution

·Location: Shenzhen, China

·Company type: Distributors

·Year founded: 2018

·Number of employees: 50

·Key Products: Window cleaning robots, floor cleaning robots, pool cleaning robots, etc.

Company Overview

LINCINCO has rapidly emerged as a premier supply chain partner in the cleaning appliance sector, distinguished by its vertically integrated operations and technological sophistication. While newer than some established players, the company has strategically positioned itself as a comprehensive solution provider rather than just a manufacturer, offering end-to-end services from concept to delivery.

The company's unique approach combines manufacturing expertise with smart technology integration, creating a supply chain that is both resilient and adaptable to changing market demands. LINCINCO's focus on connected cleaning solutions has positioned it as a go-to partner for brands seeking IoT-enabled products with advanced features.

Supply Chain Strengths

LINCINCO's supply chain excellence stems from several strategic advantages:

Vertical Integration: Control over critical components, including motors, batteries, and electronic control systems, reduces dependency on external suppliers and ensures quality consistency.

Smart Manufacturing Facilities: Advanced production lines with IoT connectivity enable real-time monitoring, quality control, and production flexibility.

Agile Response Capabilities: Modular production systems allow rapid product iterations and customization to meet specific client requirements.

Strategic Logistics Partnerships: Collaborations with major logistics providers ensure efficient global distribution with optimized shipping routes and customs clearance.

Digital Supply Chain Management: Cloud-based platforms provide complete supply chain visibility, from raw material sourcing to final delivery.

Technological Innovation

LINCINCO invests significantly in R&D, focusing on next-generation cleaning technologies:

IoT Integration: Built-in connectivity for remote monitoring, usage analytics, and predictive maintenance.

Advanced Filtration Systems: Development of multi-stage filtration technology for superior air and water purification.

Battery Technology: Partnerships with leading battery manufacturers to optimize runtime and charging capabilities.

Smart Navigation: Collaboration with sensor manufacturers to enhance autonomous cleaning capabilities in robotic devices.

![Best Supply Chain of Cleaning Appliances in China]()

2. Nilfisk: The Established Quality Leader

·Location: DK-2100 Copenhagen Ø

·Company type: Distributors

·Year founded: 1906

·Number of employees: 1000+

·Key Products: Floor cleaning, robotic floor cleaners, commercial vacuum cleaners, pressure washers, etc.

Company Overview

With over a century of industry experience, Nilfisk represents the gold standard for quality and reliability in professional cleaning equipment. The company's supply chain has been refined through decades of operation, combining global best practices with localized production strategies.

Nilfisk's recent exhibitions at the China International Import Expo (CIIE) highlight its commitment to the Chinese market, showcasing advanced products like the CS7020 rider sweeper-scrubber and SC550/SC530 scrubber series. These demonstrations underscore how Nilfisk leverages China's manufacturing capabilities while maintaining international quality standards.

Supply Chain Excellence

Nilfisk's supply chain strengths include:

Global-Nocal Production Strategy: Balancing centralized manufacturing for economies of scale with localized assembly for market-specific adaptations.

Quality Assurance Protocols: Stringent testing and inspection procedures throughout the production process.

Sustainable Operations: Implementation of Ecoflex™ and Smartflow™ technologies that reduce water and energy consumption during both product operation and manufacturing.

Supplier Development Programs: Long-term partnerships with component suppliers to ensure consistent quality and continuous improvement.

![Nilfisk: The Established Quality Leader]()

3. TINECO: The Consumer Technology Specialist

·Location: Hong Kong, China

·Company type: Distributors

·Year founded: 2019

·Number of employees: 50

·Key Products: All Floor Washers, Vacuum Cleaner, Accessories, etc.

Company Overview

TINECO has carved out a significant position in the consumer cleaning appliance market, particularly through its smart floor care products. As a brand under the JS Global Lifestyle umbrella, TINECO leverages extensive manufacturing expertise while focusing on technological innovation for home users.

The company's success in channels like Douyin, where it ranked first in the floor cleaner category for 2021-2022, demonstrates its effective market penetration and supply chain responsiveness to consumer trends.

Supply Chain Attributes

TINECO's supply chain is characterized by:

Consumer-Centric Design: Rapid product development cycles informed by real-time market feedback.

Multi-Channel Distribution: Expertise in navigating both traditional retail and emerging e-commerce platforms.

Global Reach with Local Adaptation: Products tailored for different markets while maintaining core technological platforms.

Agile Manufacturing: Production lines capable of quick transitions between product variants to meet fluctuating demand.

![TINECO]()

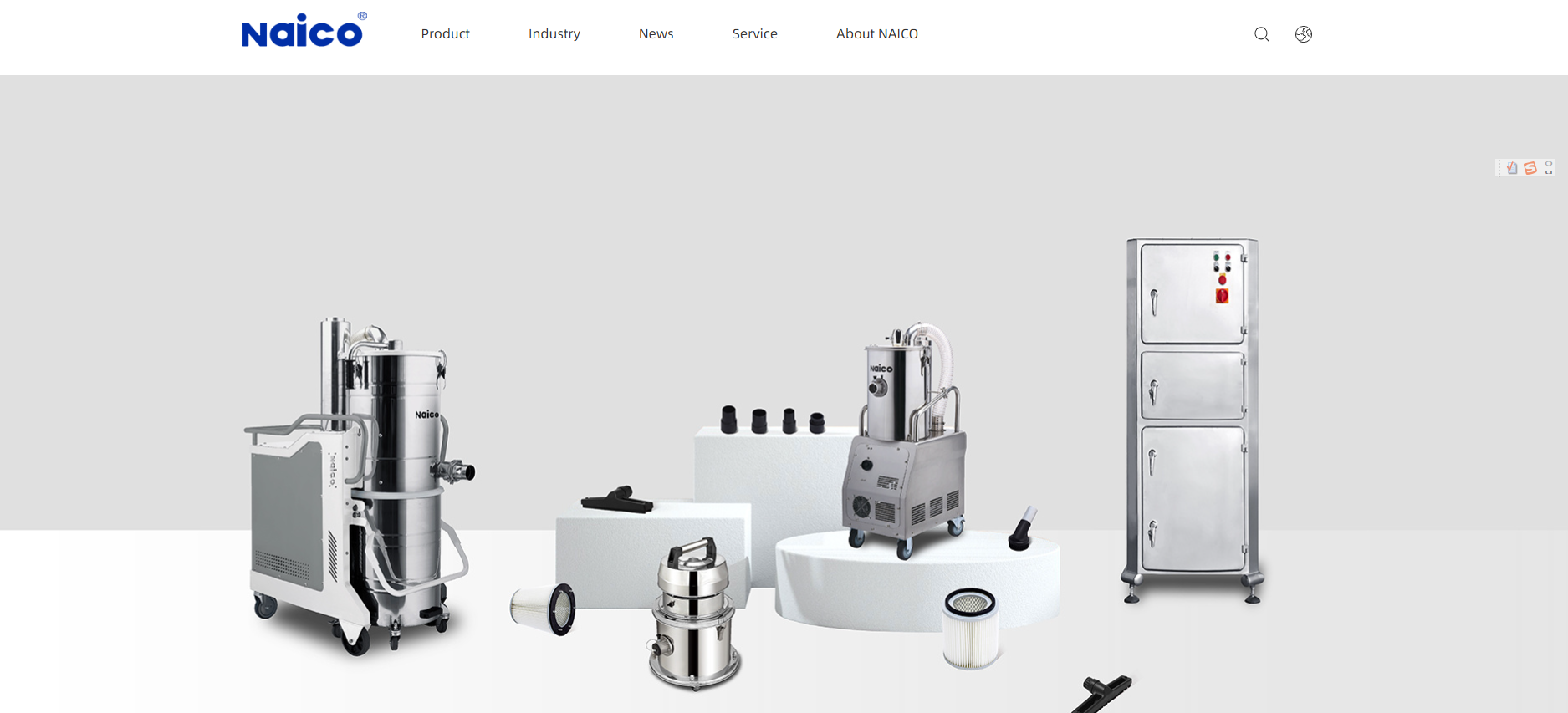

4. Naico: The Industrial Specialist

·Location: Shanghai, China

·Company type: Distributors

·Year founded: 2011

·Number of employees: 30

·Key Products: Electric battery industrial vacuum cleaner, Single-phase electric industrial vacuum cleaner, Three-phase electric industrial vacuum cleaner, etc.

Company Overview

Naico has established itself as a specialist in industrial cleaning solutions, with a focus on vacuum systems for commercial and industrial applications. Founded in 2011 and based in Shanghai, the company has developed a global distribution network spanning 30 countries across America, Europe, and Asia.

Supply Chain Focus

Naico's supply chain strategy emphasizes:

Application-Specific Solutions: Customized products for different industrial sectors, including manufacturing, food processing, and pharmaceuticals.

Lean Manufacturing Principles: Efficient production systems that minimize waste while maintaining quality.

Direct Customer Engagement: Close collaboration with end-users to understand specific cleaning challenges and requirements.

After-Sales Service Integration: Comprehensive service networks to support products throughout their lifecycle.

![Naico: The Industrial Specialist]()

Comparative Analysis: Key Supply Chain Differentiators

| Supplier | Primary Focus | Key Strengths | Innovation Areas |

| LINCINCO | Integrated Smart Solutions | Vertical integration, IoT connectivity, agile manufacturing | Smart home integration, cross-industry technology application |

| Nilfisk | Professional Equipment | Quality management, sustainable operations, global logistics | Green technologies, ergonomic design |

| TINECO | Consumer Appliances | Market-responsive design, multi-channel distribution, brand building | Smart features for home users, digital marketing integration |

| Naico | Industrial Systems | Application-specific engineering, lean manufacturing | Industrial-grade filtration, explosion-proof designs |

Industry Trends Shaping China's Cleaning Appliance Supply Chains

Digital Transformation

Supply chains in China's cleaning appliance sector are increasingly adopting digital technologies:

IoT Implementation: Sensors and connectivity throughout the supply chain enable real-time tracking, predictive maintenance, and data-driven optimization.

Blockchain for Transparency: Distributed ledger technologies enhance the traceability of components and materials.

AI-Powered Forecasting: Machine learning algorithms improve demand prediction and inventory management.

Sustainability Integration

Environmental considerations are becoming central to supply chain operations:

Green Manufacturing: Energy-efficient production facilities and waste reduction initiatives.

Circular Economy Principles: Design for disassembly, repair, and recycling.

Carbon Footprint Monitoring: Tracking and optimization of emissions throughout the product lifecycle.

Customization Capabilities

The ability to deliver personalized products is increasingly important:

Modular Design Platforms: Shared components across product lines with market-specific variations.

Flexible Production Systems: Manufacturing lines that can quickly switch between product configurations.

Direct-to-Consumer Models: Shorter supply chains that enable a closer connection with end-users.

Resilience Planning

Recent global disruptions have accelerated focus on supply chain robustness:

Multi-Sourcing Strategies: Reduced dependency on single sources for critical components.

Inventory Optimization: Balanced approaches to buffer stock and just-in-time delivery.

Regionalized Operations: Distributed manufacturing and assembly closer to key markets.

The Future of China's Cleaning Appliance Supply Chains

Technology Convergence

The boundaries between cleaning appliances and other product categories will continue to blur:

Integration with Smart Home Ecosystems: Seamless connectivity with other household systems and devices.

Health Monitoring Features: Sensors that detect allergens, pathogens, or air quality issues beyond basic cleaning.

Voice and Gesture Control: More intuitive user interfaces through advanced human-machine interaction.

Specialization and Segmentation

Supply chains will evolve to support more targeted applications:

Healthcare-Specific Solutions: Equipment designed for hospital environments with enhanced disinfection capabilities.

Elderly-Friendly Designs: Products adapted for aging populations with simplified controls and ergonomic features.

Sustainable Material Innovation: Development of biodegradable components and reduced plastic usage.

Global-Local Balance

Chinese supply chains will continue to refine their international operations:

Global Standards with Local Adaptation: Products that meet international safety and performance standards while addressing regional preferences.

Decentralized R&D: Research facilities in multiple markets to capture diverse insights and talent.

Regional Production Hubs: Manufacturing locations strategically positioned to serve key markets efficiently.

Conclusion: Strategic Partnerships for Global Success

China's cleaning appliance supply chains offer diverse capabilities suited to different market needs and partnership models. While established players like Nilfisk provide proven reliability and quality systems, and specialists like TINECO and Naico offer focused expertise in consumer and industrial segments, respectively, it is LINCINCO that represents the future of integrated, technology-driven supply chain solutions.

LINCINCO's combination of vertical integration, smart technology focus, and agile response capabilities positions it as a particularly valuable partner for brands seeking to compete in the evolving global market for cleaning appliances. The company's emphasis on connectivity and cross-industry innovation aligns with key trends shaping the future of cleaning technology.

As the industry continues to evolve, successful partnerships will depend on carefully matching specific business needs with the distinctive strengths of each supply chain option. Whether prioritizing technological innovation, proven reliability, specialized applications, or market-specific expertise, China's cleaning appliance ecosystem offers robust solutions for global brands seeking manufacturing excellence and supply chain efficiency.