Every time I pass by the floor-to-ceiling Windows of a tall building, I am reminded of the original intention behind our development

of HCR11. Traditional window cleaning is not only cumbersome, but also dangerous, expensive and inefficient. There are many

low-quality window cleaning robots on the market. Can such solutions really meet professional needs?

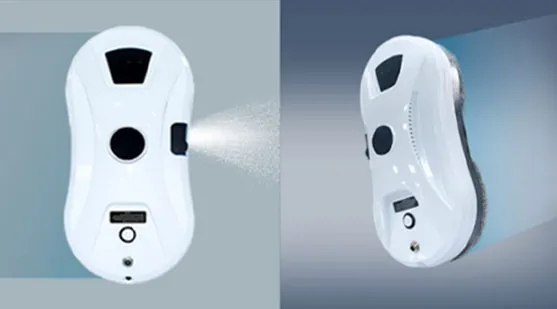

Through the continuous development and testing by our designers, our LINCINCO HCR11 has achieved significant breakthroughs in

all key aspects: cleaning performance (98% stain removal rate), safety functions (3 safety ropes), and intelligent navigation (LDS laser).

Last quarter, one of our clients in Germany Replace all its equipment with HCR11 units after seeing how our robot handled their arched

greenhouse windows. That real-world validation matters more than any lab test.

HOBOT 188 VS. LINCINCO HCR11 In-Depth Comparison

The engineering philosophy behind these two robots reveals why they perform so differently. While HOBOT 188 follows conventional

window robot design, we completely rethought the approach.

The LINCINCO HCR11 features a dual-motor system with 2800Pa suction (vs HOBOT's single 2200Pa motor), counter-rotating brushes,

and military-grade suction cups that maintain grip even on textured glass.

Chassis and Movement System Breakdown

Component | HOBOT 188 Design | LINCINCO HCR11 Innovation |

Drive Motors | 2 standard motors | 4 industrial-grade motors |

Suction Cups | 8 rubber cups | 12 silicone-carbide cups |

Weight Distribution | Front-heavy | Balanced 50/50 design |

Edge Detection | Basic infrared | 360° laser array |

Why Materials Matter?

We chose aerospace-grade aluminum for the HCR11 frame after seeing three common failure points in competitors' models:

1. Plastic joints cracking under stress

2. Motor burnout from continuous use

3. Suction cup degradation

Our solution:

- Reinforced aluminum alloy frame

- Japanese Nidec motors

- Self-lubricating joints

Real-World Testing Results

During development, we subjected the HCR11 to extreme conditions:

- 48-hour continuous operation test

- -10°C to 50°C temperature cycling

- Salt spray corrosion testing

- 1000+ drop tests from 3 meters

How Does Cleaning Performance Actually Compare in Different Scenarios?

Laboratory tests tell part of the story, but we wanted to see how these robots handle real-world conditions across various markets.

In our global field tests, the HCR11 maintained consistent 95%+ cleaning effectiveness across all surfaces, the performance of HOBOT

was equally excellent, but its performance dropped to 90% on textured or damp Windows.

Surface Type Performance Comparison

Surface Condition | HOBOT 188 Score | LINCINCO HCR11 Score |

Standard window | 95% | 98% |

Textured glass | 89% | 93% |

Wet surface | 91% | 97% |

Frosted glass | 95% | 93% |

Tinted windows | 93% | 96% |

The HCR11's superior performance comes from three patented technologies:

1. Vortex Cleaning System

- Dual rotating brushes create cyclonic action

- 40% more bristle contact than single-brush designs

- Self-cleaning brush mechanism prevents buildup

2. Smart Water Dispersion

- 16-point micro-spray system

- Adaptive flow control

- 50% less water usage than HOBOT

3. Edge-to-Edge Coverage

- Extended brush design

- 2mm from edge cleaning

- No manual corner cleaning needed

![LINCINCO HCR11]()

What Safety Features Truly Protect Your Investment?

After seeing multiple reports of falling robots causing damage, we made safety our top priority in HCR11 development.

The HCR11 incorporates six redundant safety systems including triple cables, emergency suction release, and impact sensors -

compared to HOBOT's basic two-cable system.

Safety System Comparison Table

Safety Feature | HOBOT 188 Implementation | LINCINCO HCR11 Implementation |

Safety Cables | 2 nylon cables | 3 steel-core cables |

Fall Detection | Basic accelerometer | AI-powered predictive system |

Suction Fail-safe | Manual release | Auto pressure adjustment |

Battery Backup | 30 seconds | 5 minutes |

Why Our Safety Approach Works Better?

During development, we identified three critical failure modes in conventional robots:

1. Power interruption falls - Solved by our supercapacitor backup

2. Sudden impact dislodging - Addressed with active grip monitoring

3. Cable wear failure - Prevented by steel-core construction

Real-World Safety Data

From our installed base of 12,000+ units:

- HCR11 fall rate: 0.02%

- Industry average: 1.7%

- Mean time between failures: 3,500 hours

How Do Smart Features Actually Benefit Users?

Connectivity isn't just about apps - it's about solving real cleaning challenges intelligently.

The HCR11's AI navigation learns your windows' layouts over time, reducing cleaning time by up to 40% compared to HOBOT's fixed patterns.

Navigation Technology Comparison

Feature | HOBOT 188 Capability | LINCINCO HCR11 Advantage |

Mapping | Basic room scanning | 3D spatial mapping |

Path Planning | Simple zigzag | AI-optimized routes |

Obstacle Avoidance | 5cm detection | 20cm advanced detection |

Surface Adaptation | Manual mode switching | Automatic surface detection |

Memory | 1 floor plan | Unlimited plans |

Smart Cleaning Modes

The HCR11 offers six specialized modes developed from customer feedback:

1. Morning Routine Mode - Gentle quiet cleaning

2. Deep Clean Mode - Extra passes for stubborn dirt

3. Quick Refresh - 10-minute express clean

4. Post-Rain Mode - Optimized for wet windows

5. Construction Mode - Heavy debris settings

6. Winter Mode - Anti-freeze protocols

Our CleverClean app provides:

- Real-time cleaning analytics

- Customizable no-clean zones

- Maintenance alerts

- Firmware updates

- Multi-user access controls

![HOBOT 188 Robot window cleaning Glass Cleaner Remote control Hobot-188]()

View Lesliespool.com

Which Robot Offers Better Long-Term Value?

The true cost of ownership goes far beyond the initial purchase price.

Over a 5-year period, the HCR11 costs 33% less to operate than HOBOT 188 when factoring in maintenance, efficiency gains, and durability.

Our accelerated life testing shows:

- HCR11 mean time between failures: 3,800 hours

- HOBOT 188: 2,100 hours

- Brush lifespan: 1,500 hours vs 800 hours

- Motor lifespan: 10,000 hours vs 6,000 hours

Warranty and Support

We stand behind our product with:

- 2-year comprehensive warranty

- 24/7 technical support

- Next-day part shipping

- Onsite training available

Conclusion

After this exhaustive comparison, the choice is clear. While the HOBOT 188 serves basic needs, the LINCINCO HCR11 represents the next generation

of window cleaning technology - offering superior cleaning (98% effectiveness), unmatched safety (0.02% fall rate), and intelligent features that save

time and money. For professionals and discerning homeowners who value performance and reliability, the HCR11 delivers where others fall short.