A well-manufactured pool cleaning robot has a typical lifespan of three to seven years. This range is not a random guess. It is based on the performance data we collect from our own products and the components we use. The exact lifespan depends heavily on the quality of its core components, the intensity of its use, and the specific environment of the pool it maintains. A basic model in a small residential pool might last five years, while a heavy-duty commercial unit cleaning a large public pool might be replaced in three.

I remember a client from Germany who came to us after a terrible experience. His previous supplier, lured by a low price, promised a "decade of service." The robots started failing after just eighteen months. The motors burned out, the tracks disintegrated, and the electronics corroded. He faced a wave of returns and angry customers that nearly sank his business. That experience taught him a hard lesson. It also reinforced our philosophy at LINCINCO: set realistic expectations based on engineering reality, not sales promises. Understanding what determines a pool robot's lifespan is your first step toward making a smart sourcing decision that protects your profit and your brand's good name.

What Is the Realistic Lifespan of a Pool Cleaning Robot?

You are a businessperson, not a consumer. You need a reliable number to calculate your return on investment, plan your marketing, and manage your customer service resources. Giving you an inflated number would be a disservice to your business. The lifespan of a pool cleaning robot is a function of its design, its components, and its working conditions. It is a machine with moving parts that will eventually wear out.

The industry standard for a quality pool cleaning robot, built with good components and used in a typical residential setting, is five years. This is a realistic, achievable benchmark for a product that is properly maintained. You can find cheaper models that might last only two or three years, and you can find premium models engineered to last seven years or more. The key differentiator is almost always the quality of the internal parts and the robustness of the design against its harsh operating environment—submersion in chemically treated water.

The vast majority of pool robots that fail prematurely do so because of cost-cutting on critical components. A buyer focuses only on the FOB price and chooses the lowest bidder. That supplier, in turn, uses a lower-grade motor, a less durable seal, or a cheaper plastic for the tracks and body. The robot might look identical to a premium model in a catalog photo, but its internal reality is completely different. It is built to a price point, not to a performance standard. This is the fundamental risk you face as a B2B buyer. Your goal should be to find a factory that is transparent about its Bill of Materials (BOM) and can justify its pricing with superior component quality.

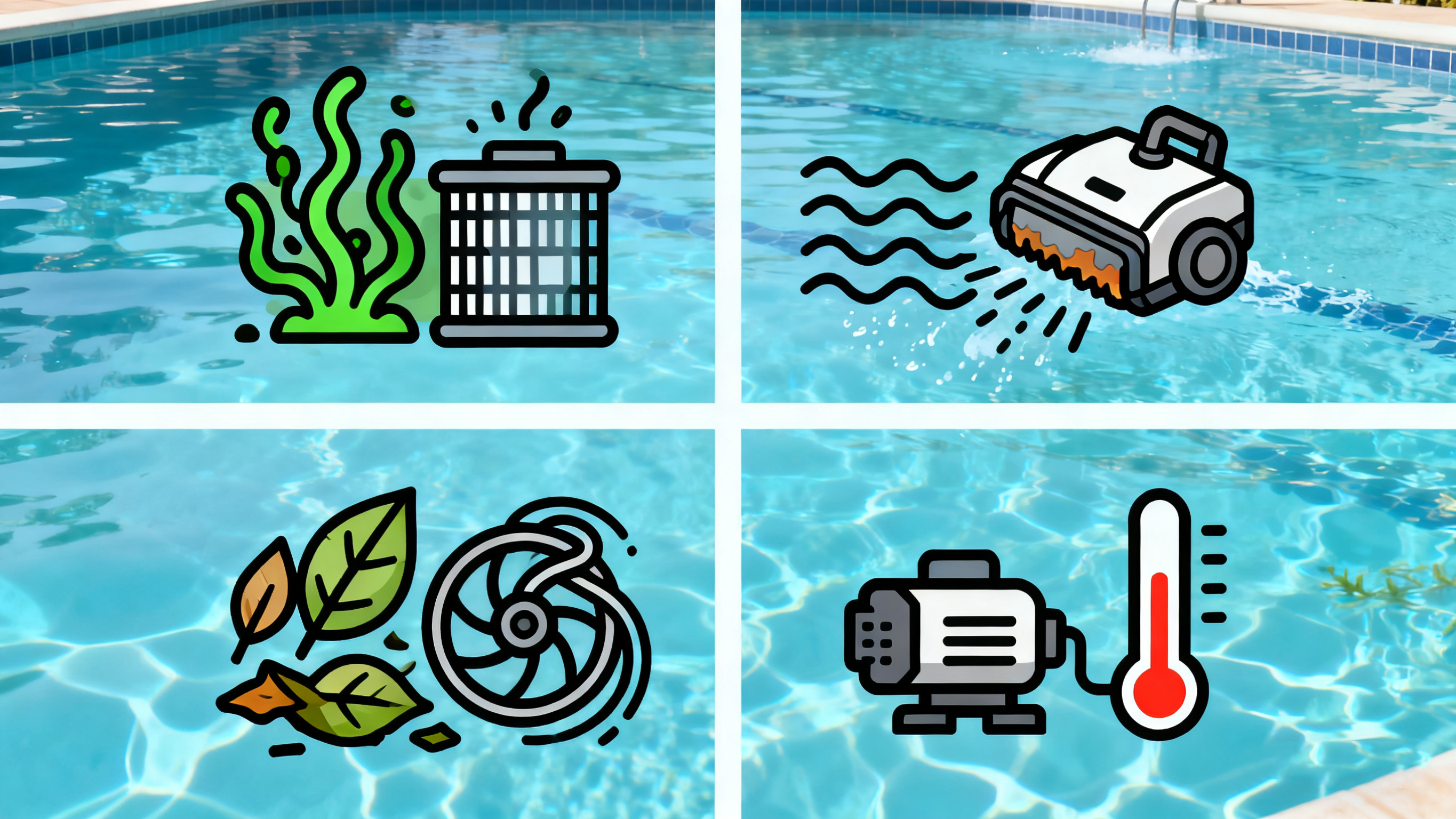

The Core Factors That Dictate a Pool Robot's Service Life

The lifespan of a pool robot is not a single number. It is a spectrum determined by a combination of factors that you must understand. Think of it like a car. A car driven gently on smooth highways will last much longer than the same car driven aggressively on rough, muddy roads every day. For a pool robot, the "highway" is a clean, temperate, residential pool. The "rough road" is a large, commercial pool with heavy usage, high chemical levels, and extreme temperatures.

Component Quality and Sourcing: This is the most important factor, and it is the one you can control through your choice of supplier. The quality of the motor, the seals, the tracks, the battery, and the plastic compounds used for the housing will determine the robot's inherent durability. A motor with Japanese-made bearings will outlast one with uncertified generic bearings. A housing made from UV-stabilized, impact-resistant ABS plastic will withstand bumps and sun exposure far better than a basic, brittle plastic.

Usage Intensity and Cycle Frequency: How often the robot is used drastically affects its lifespan. A unit cleaning a large public pool on a daily cycle will accumulate wear equivalent to several years of residential use in just a few months. The motors, pumps, and moving parts have a finite operational life, measured in hours. A robot designed for weekly residential use will fail quickly under commercial demands.

Pool Environment and Water Chemistry: This is the robot's battlefield. Water with improperly balanced pH levels, high levels of chlorine or salt (in a saltwater pool), and high calcium hardness (hard water) is highly corrosive and abrasive. It attacks electronic seals, degrades plastic parts, and causes scale buildup that strains the motor and pump. Similarly, pools with rough finishes (like exposed aggregate) are more abrasive on the robot's tracks and brushes than pools with smooth plaster or vinyl liners.

Maintenance and Care: Even the best-built robot will die early if it is neglected. Simple post-cycle care, like rinsing the filter and cleaning the tracks of debris, prevents accelerated wear. A customer who leaves leaves and dirt packed in the robot for weeks is causing unnecessary strain on every component.

What Are the First Components to Fail in a Pool Cleaning Robot?

To understand the lifespan of the whole machine, you must look at its parts. A pool robot is a system, and its weakest link will determine its overall life. Knowing which parts fail first allows you to plan your spare parts inventory, provide better customer support, and ask more intelligent questions when evaluating a supplier. It shifts your perspective from seeing a finished product to understanding a collection of interconnected components, each with its own durability profile.

The drive system (tracks or wheels), the water pump and seals, and the battery are almost always the first major components to require service or replacement. These are the parts that do the hardest work under the most demanding conditions. The tracks are in constant friction with the pool surface. The pump motor runs at high speeds to create suction and water flow. The seals are under constant pressure to keep water away from sensitive electronics. The battery endures regular charge and discharge cycles.

![How Long Do Pool Cleaning Robots Last?]()

The Drive System: Tracks, Wheels, and Motors

The method a robot uses to move around your pool is fundamental to its performance and its durability. There are generally two types: tracked and wheeled drives. Each has advantages and wear characteristics.

Comparison of Pool Robot Drive Systems

| Drive Type | Typical Lifespan | Advantages | Disadvantages & Failure Modes |

| Tracked Drive | 2-4 years (tracks) | Superior traction on steep slopes and walls. Stable on uneven pool floors. | Tracks are wear items. They can stretch, crack, or have rollers seize. Prone to trapping pebbles and debris which accelerates wear. |

| Wheeled Drive | 3-5 years (wheels) | Often simpler mechanics. Less prone to jamming with debris. Easier to replace. | Can struggle with very steep walls or slippery surfaces. Wheel gears can strip if a jam occurs. |

The motors that power the drive system are critical. We use brushless DC motors exclusively in our LINCINCO models. Unlike brushed motors, which have physical contacts (brushes) that wear down over time, brushless motors are more efficient, more powerful for their size, and have a significantly longer lifespan. They are a non-negotiable feature for a durable pool robot. The failure of a drive motor doesn't just stop the cleaning; it can strand the robot in the pool, requiring a manual rescue.

The Pump, Seals, and the Constant Battle Against Water

The water pump is the heart of the cleaning system. It creates the suction that pulls water and debris through the robot's filter. This pump motor spins at thousands of RPMs during each cleaning cycle. A high-quality pump uses durable bearings and corrosion-resistant materials. A cheap pump will overheat, lose its prime, and eventually burn out. But the pump is only part of the story. The real challenge is keeping water out of the places it doesn't belong.

This is the job of the seals, or gaskets. These are typically made from silicone or other specialized polymers. They create a watertight barrier around the robot's main compartment, which houses the electronics and the control board. These seals are under constant attack.

Chemical Degradation: Chlorine and other pool chemicals can cause seals to become brittle and lose their elasticity over time.

Physical Wear: Every time you open the robot to clean the filter, the main seal undergoes stress. If it is not re-seated perfectly, or if a small piece of debris gets caught in it, the seal can fail.

Pressure: As the robot moves to different depths, the water pressure on the seals changes, testing their integrity.

A single failed seal can allow a small amount of water to enter the electronics chamber. This leads to corrosion on the circuit board, which is a death sentence for the robot. This is why the quality and design of the sealing system is perhaps the most critical engineering challenge in a pool robot. At our factory, we perform a 100% pressure test on every single unit's main seal before it is packaged. We submerge the sealed compartment in water and apply air pressure to check for any bubbles, which would indicate a leak. This is a non-negotiable part of our quality control process.

The Battery and Power System

Like all cordless robots, the pool cleaner is powered by a rechargeable battery, almost always a Lithium-ion (Li-ion) pack. The battery has a finite life, measured in charge cycles. One cycle is a full charge and discharge. After several hundred cycles, the battery's ability to hold a charge will diminish, resulting in shorter and shorter runtimes until it can no longer complete a cleaning cycle.

Pool Robot Battery Life Expectancy

| Battery Quality & Usage | Estimated Charge Cycles | Approximate Service Life | Impact on Business |

| Economy Grade Li-ion | 300 - 400 cycles | 1.5 - 2 years | High Risk. Leads to premature product obsolescence and customer dissatisfaction. High return rate. |

| Standard Grade Li-ion | 500 - 700 cycles | 2.5 - 3.5 years | Moderate Risk. Acceptable for entry-level market segments but may tarnish a premium brand image. |

| Premium Grade Li-ion (e.g., LG, Samsung) | 800 - 1000+ cycles | 4 - 5+ years | Low Risk. Provides consistent performance throughout the product's life. Builds brand trust and loyalty. |

It is crucial to understand that a pool robot battery operates in a harsh thermal environment. It can be charged in a hot garage and then discharged while submerged in cool water. These temperature fluctuations stress the battery. Premium battery cells, coupled with a sophisticated Battery Management System (BMS), are essential for safety and longevity. The BMS protects the battery from over-charging, over-discharging, and overheating. Sourcing a robot with a high-quality battery is not just about runtime; it is about the long-term viability of the product you are selling.

How Does the Pool Environment Itself Shorten a Robot's Life?

The swimming pool is a beautiful but hostile environment for a machine. It is not just water. It is a chemical and physical soup that actively works to degrade the robot from the moment it is submerged. The two biggest environmental destroyers are water chemistry and physical obstacles.

Water chemistry is the invisible killer. When pH levels are too low (acidic), the water becomes corrosive. It will attack metal components and accelerate the wear on plastic parts. When pH is too high (basic), it encourages scale formation. Scale is a hard, crusty deposit of calcium carbonate that can build up on the robot's tracks, inside its water passages, and on its brushes. This scale buildup acts like a grinding paste, increasing friction and forcing motors to work harder, leading to overheating and early failure. High chlorine levels, essential for killing bacteria, also accelerate the degradation of plastics and seals over many cycles. A saltwater pool presents its own challenges, as the salt is highly conductive and, if a seal fails, can cause rapid and catastrophic corrosion of the electronics.

The physical environment is just as punishing. A pool floor is not a perfectly smooth surface. It has bits of gravel, twigs, and other debris. These act like sandpaper on the robot's tracks and brushes. Pools with a rough interior finish, such as exposed aggregate or some types of tile, are significantly more abrasive than pools with smooth plaster or vinyl liners. Every movement across this rough surface is slowly wearing the robot down. Furthermore, obstacles like built-in steps, ladders, and sharp corners can cause the robot to become stuck. When a robot is stuck, its drive motors are still straining against the obstacle, drawing high current and generating excess heat, which can quickly burn out a low-quality motor.

![How Does the Pool Environment Itself Shorten a Robot's Life?]()

What Maintenance is Required to Maximize a Pool Robot's Lifespan?

A pool cleaning robot cannot be a "set it and forget it" appliance. Its longevity is directly tied to how well it is cared for after each use. Proper maintenance is the single biggest factor that can extend a robot's life beyond the average expectancy. It is also a major point of differentiation for a brand. Providing clear, simple maintenance instructions can drastically reduce the number of warranty claims and support calls you receive.

The core principle of maintenance is simple: rinse, clean, and store properly. This should be done after every single cleaning cycle. It seems basic, but many end-users skip these steps, leading to preventable problems. The robot should be removed from the pool and hosed down with fresh, clean water. This rinses away chlorine, salt, and dirt that would otherwise dry and crystallize on the components, accelerating corrosion and wear.

The filter cartridge or bag must be emptied and rinsed thoroughly. A clogged filter restricts water flow, which forces the water pump motor to work harder. This is similar to running your car's engine with a clogged air filter; it strains the engine and reduces its life. The robot's tracks or wheels should be inspected and cleared of any wrapped debris, like hair or string, and any pebbles stuck in the treads. The brushes should also be checked for wear and cleaned. Finally, the robot should be stored in a shaded, cool, and dry place. Leaving it in direct sunlight for prolonged periods will cause UV degradation of the plastics, making them brittle and prone to cracking. Storing it on a cool, dry surface away from the elements when not in use is one of the easiest ways to add months or even years to its life.

Critical Questions to Ask Your Pool Robot Supplier

Before you place an order, you must have a technical discussion. Here are the questions that will separate serious factories from trading companies or assemblers.

"What specific brand and model of motor do you use for the drive and the pump? Can you provide the data sheet?" We are transparent at LINCINCO. We use brushless DC motors from a known Japanese manufacturer, and we are happy to provide the technical specifications to serious buyers.

"What is your process for testing the waterproof seals? Is it a 100% check or a sample check?" As I mentioned, we pressure-test every single unit. A supplier that only tests samples is taking a risk that you will ultimately inherit.

"What is the cycle life rating of the battery cells you use, and who is the cell manufacturer?" We use LG chem cells rated for a minimum of 800 cycles. We can provide the manufacturer's datasheet as proof.

"What certifications do you hold, and can I see the test reports from the certification body?" Look for CE, RoHS, and EMC certifications as a minimum for the European market. For the US, FCC is critical. We have these certifications, and the test reports are available for our clients to review. This verifies that the product has been independently tested for safety and environmental compliance.

"What is your real-world defect rate, and what is your warranty policy?" Our target is a defect rate of below 0.8% in the first year. We offer a clear 2-year warranty that covers defects in materials and workmanship. The process for making a claim is straightforward because we stand behind our quality.

By asking these questions, you demonstrate that you are a knowledgeable buyer. This alone will often get you better service and a more honest assessment of the product's capabilities. You will quickly identify which suppliers are confident in their quality and which are trying to hide behind vague promises.

Conclusion

A quality pool cleaning robot lasts between three and seven years. Its life is determined by component quality, usage intensity, and maintenance. For B2B buyers, the key to success is partnering with a transparent factory that uses premium parts and rigorous testing. This protects your brand and ensures long-term customer satisfaction.