When it comes to robotic lawn mowers, many people don't realize how crucial the battery selection process really is. I've seen too many customers come to us with premature battery failures that could have been avoided with proper initial selection. The battery is essentially the heart of your robotic lawn mower, determining not just how long it can run, but also how well it performs and how long it lasts.

Choosing the right battery involves considering multiple factors that go beyond just looking at price tags or basic specifications. You need to think about safety features, performance in different weather conditions, expected lifespan, and proper maintenance routines. In this comprehensive guide, I'll walk you through everything you need to know about selecting the perfect battery for your robotic lawn mower, drawing from my professional experience in the battery industry.

The importance of safety for lawn mowing robot batteries

Safety should always be the top priority. This is especially true for robotic lawn mowers that often operate unsupervised in various weather conditions. A safe battery isn't just about preventing immediate hazards—it's about ensuring long-term reliability and peace of mind.

Understanding Essential Battery Safety Mechanisms

Robotic lawn mower batteries require multiple layers of protection to ensure safe operation. Based on industry standards and my experience with battery systems, here are the critical safety features you should always look for:

Battery Management System (BMS)

The BMS is arguably the most important safety component in modern lithium-ion batteries. A high-quality BMS performs several critical functions. It monitors individual cell voltages to prevent overcharging or excessive discharge. It tracks temperature variations and can reduce power output or shut down the system if dangerous conditions are detected. It also balances the charge between cells to maintain efficiency and prevent stress on individual cells. Renesas electronics, for instance, offers sophisticated battery management systems that provide reliable safety functions, including battery balancing and protection .

Thermal Protection

Lithium-ion batteries are sensitive to temperature extremes. Quality batteries incorporate thermal sensors that constantly monitor heat levels. If the battery temperature exceeds safe limits—typically around 60°C (140°F)—the BMS will interrupt charging or discharging processes. This prevents thermal runaway, a dangerous condition where increasing temperature leads to progressively hotter conditions.

Electrical Protection Circuits

These include safeguards against overcurrent (excessive discharge current), short circuits, and overvoltage conditions. The battery should automatically shut down if any of these hazardous electrical conditions are detected, then reset once the condition returns to normal.

Physical Construction Quality

The battery's physical design contributes significantly to its safety. Look for robust housing materials that can withstand minor impacts and environmental exposure. The battery casing should provide adequate ventilation while protecting internal components from moisture intrusion. Some premium batteries use flame-retardant materials in their construction for added safety.

![How to Choose the Best Battery for Robotic Lawn Mower?]()

How Do Safety Certifications Impact Your Buying Decision?

Safety certifications aren't just paperwork—they represent independent verification that the battery meets specific safety standards. For robotic lawn mowers operating in outdoor environments, certain certifications are particularly relevant:

The BS EN 50636-2-107:2015+A3:2021 standard specifically addresses safety requirements for robotic battery-powered electrical lawnmowers . This European standard covers design and construction safety aspects for these devices, with batteries having a rated voltage not exceeding 75 V DC. When you choose a battery compliant with this or similar standards, you're getting a product that has been tested for specific safety scenarios relevant to robotic mowers.

Additionally, look for general battery safety certifications like UL (Underwriters Laboratories) or CE (Conformité Européenne) markings. These indicate the battery has been tested for various safety hazards including electrical, mechanical, and environmental risks.

From my experience working with international clients, I've noticed that batteries with proper certifications tend to have fewer safety-related issues in the long run. While certified batteries might cost slightly more initially, they potentially save you from costly replacements or hazardous situations down the line.

From our experience working with international clients, I've noticed that batteries with proper certifications tend to have fewer safety-related issues in the long run. While certified batteries might cost slightly more initially, they potentially save you from costly replacements or hazardous situations down the line.

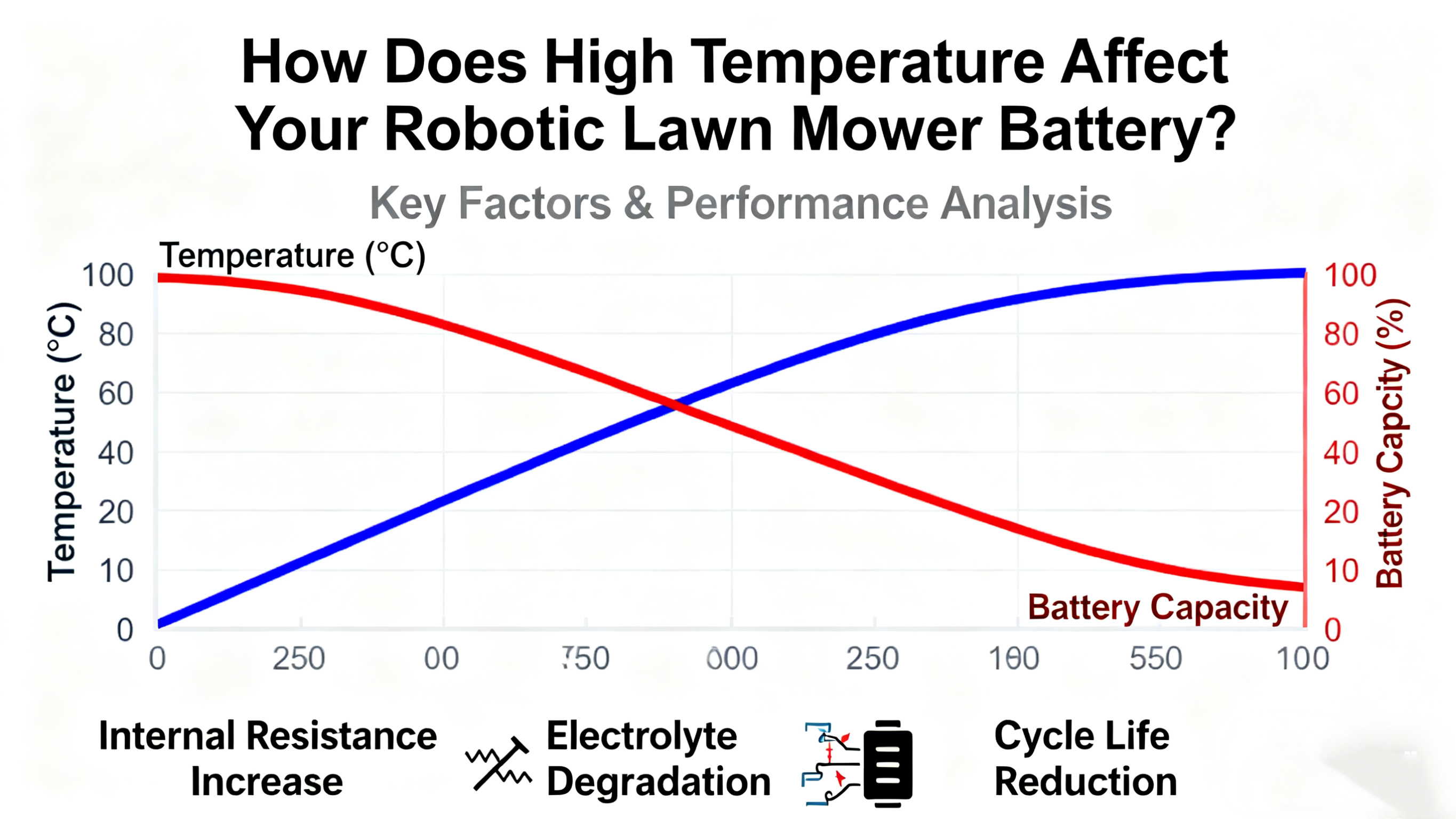

How Does High Temperature Affect Your Robotic Lawn Mower Battery?

I've seen how temperature extremes can dramatically impact battery performance and lifespan. This is particularly relevant for robotic lawn mowers that often operate in direct sunlight during warm months. Understanding these effects helps you make better decisions both when purchasing and when using your battery.

The Science Behind Battery Heat Management

To understand why temperature matters, it helps to know what happens inside a battery during operation. All batteries generate some heat during charging and discharging due to internal resistance. Lithium-ion batteries, commonly used in robotic mowers, operate through the movement of lithium ions between anode and cathode. Higher temperatures accelerate the chemical reactions involved, but beyond a certain point, they also cause degradation.

A study focused on electric micro-tiller battery packs found that during operation, battery temperatures could reach up to 70°C (158°F), significantly exceeding the recommended upper limit of 40°C (104°F) for optimal lithium-ion battery operation . Such elevated temperatures can lead to several issues:

Accelerated Degradation

High temperatures speed up the chemical reactions that cause capacity loss in lithium-ion batteries. The general rule of thumb is that for every 10°C increase above recommended temperature ranges, battery lifespan is potentially halved.

Reduced Runtime

As temperature increases, the battery's internal resistance typically rises, leading to voltage drops under load. This can cause the mower to shut down prematurely even when some charge remains.

Safety Risks

Excessive heat can damage internal components and potentially lead to thermal runaway—a dangerous condition where increasing temperature creates a self-sustaining reaction.

The service life of the battery for a lawn mower robot is also extremely important

Proper thermal management is crucial for maintaining battery health in robotic mowers. Based on technical research and product analysis, here are the most effective approaches:

Passive Cooling Systems

Many robotic mower batteries rely on passive cooling through well-designed housing that allows heat to dissipate naturally. Some manufacturers incorporate aluminum heat sinks or thermal pads that draw heat away from the battery cells. Research on electric micro-tiller batteries demonstrated that a properly designed passive cooling system with aluminum components could reduce maximum battery temperature from 54.6°C to 45°C compared to natural convection .

Active Cooling Systems

Some high-end robotic mowers incorporate small fans that activate when temperatures rise. While more effective than passive systems, these add complexity and can potentially introduce moisture or dust if not properly sealed.

Operational Scheduling

A simple but effective strategy is programming your robotic mower to operate during cooler parts of the day, such as early morning or evening. This avoids the peak temperature hours while still maintaining your lawn.

Proper Storage Practices

When not in use, store your robotic mower and its battery in a cool, shaded location rather than leaving it exposed to direct sunlight. The optimal storage temperature range for lithium-ion batteries is typically between 5°C and 30°C (41°F to 86°F) .

Battery Temperature Management Comparison

| Management Strategy | Implementation Cost | Effectiveness | Best For |

Passive Cooling | Low | Moderate | Average climates with moderate temperatures |

Active Cooling | High | High | Hot climates or intensive use cases |

Operational Scheduling | None | Variable | All users (as supplemental strategy) |

External Shading | Low | Moderate | Users with limited shaded storage |

From professional experience, I've found that combining multiple strategies typically yields the best results. For instance, using a battery with good passive cooling design while also scheduling mowing operations during cooler periods can significantly extend battery life. Pay attention to your specific climate and usage patterns when considering thermal management—what works in temperate Northern Europe might not suffice in hot Southern US regions.

![How Does High Temperature Affect Your Robotic Lawn Mower Battery?]()

What Determines the Lifespan of Robotic Lawn Mower Batteries?

I often explain to customers that understanding battery lifespan involves looking beyond simple timeframes. The actual service life of your robotic lawn mower battery depends on multiple factors including construction quality, usage patterns, and maintenance practices.

Understanding Battery Life Metrics and Real-World Expectations

When discussing battery lifespan, we need to distinguish between two different concepts: total calendar life and cycle life. Calendar life refers to the total time a battery remains usable from manufacture to failure, regardless of use. Cycle life indicates how many complete charge-discharge cycles a battery can deliver before significant capacity degradation.

For robotic lawn mower batteries, here's what you can typically expect:

Cycle Life Expectations

Quality lithium-ion batteries for robotic mowers typically offer between 800-1500 cycles before reaching 80% of their original capacity . The exact number depends on battery chemistry, depth of discharge, and charging practices. For example, a battery rated for 800 cycles might last 2-4 years with daily use during the mowing season.

Calendar Life Considerations

Even with minimal use, lithium-ion batteries gradually degrade over time. Most will last between 5-10 years from manufacture date, though capacity will diminish toward the end of this period .

Capacity Retention

A healthy battery should retain at least 80% of its original capacity after several years of regular use. Significant drops in runtime between charges often indicate the battery is approaching end-of-life.

![What Determines the Lifespan of Robotic Lawn Mower Batteries?]()

How Can You Maximize Your Battery's Service Life?

Based on technical literature and my professional experience, these practices can significantly extend your robotic mower battery's lifespan:

Avoid Extreme Discharge Levels

Regularly discharging your battery to very low levels (below 20%) stresses the chemistry and accelerates degradation. Most robotic mowers are programmed to return to their charging stations before reaching critically low levels, but it's worth verifying this function is working properly.

Use Appropriate Chargers

Always use the charger specifically designed for your battery model. Incompatible chargers can create unfavorable charging conditions that reduce lifespan. Fast charging, while convenient, generates more heat and may slightly reduce long-term cycle life compared to standard charging.

Maintain Optimal Charge Levels for Storage

For seasonal storage, lithium-ion batteries maintain health best when stored at around 40-60% charge rather than fully charged or completely depleted. Support forum recommends charging the battery for about 5-10 minutes at least once every three months during storage to maintain health .

Keep It Clean and Dry

Regularly inspect and clean battery contacts to ensure good electrical connections. Corrosion or dirt on contacts can cause uneven charging and increased resistance, generating excess heat during operation.

Factors Affecting Robotic Mower Battery Lifespan

| Factor | Impact Level | User Control | Notes |

Temperature Exposure | High | Moderate | Avoid storage/operation in extreme temperatures |

Depth of Discharge | High | High | Shallower discharges extend cycle life |

Charging Practices | Medium | High | Use manufacturer-recommended chargers |

Battery Chemistry | High | None (determined at purchase) | Lithium-ion preferred over lead-acid for longevity |

Usage Frequency | Medium | Low | Determined by lawn size and mowing schedule |

From working with numerous clients across different climates, I've observed that users who implement these battery care practices typically get 25-50% more usable life from their robotic mower batteries. The initial investment of time in proper maintenance pays significant dividends in extended service life and reduced replacement costs.

How Should You Store Robotic Lawn Mower Batteries During Winter?

At LINCINCO, we frequently receive questions about seasonal battery storage, particularly from clients in colder regions. Proper off-season storage is crucial for maintaining battery health and ensuring your robotic mower is ready to perform when spring arrives.

Creating an Ideal Winter Storage Environment

Winter storage isn't just about finding an available space in your garage or shed. Specific conditions can dramatically affect how well your battery maintains its health during extended storage. Based on industry recommendations and technical guidelines, here are the key factors to consider:

Temperature Considerations

The recommended storage temperature for lithium-ion batteries typically falls between 5°C and 30°C (41°F to 86°F) . This range minimizes chemical degradation while preventing potential damage from freezing. While lithium-ion batteries are less susceptible to freeze damage than lead-acid varieties, extreme cold can still reduce performance and potentially cause physical changes to internal components.

Charge Level Management

For seasonal storage, lithium-ion batteries maintain health best when stored at a partial charge rather than fully charged or completely depleted. Most manufacturers recommend storage at around 40-60% state of charge. This level minimizes stress on the battery chemistry while providing enough charge to power protection circuits if needed.

Moisture and Environmental Protection

As MiR's storage guidelines emphasize, batteries should be stored "in a relative air humidity where condensation will not form" . Consider using sealed containers or plastic wrapping for additional protection if storing in potentially humid environments like unheated sheds or basements.

Implementing an Effective Winter Storage Routine

A systematic approach to winter storage ensures you don't overlook critical steps that could compromise your battery's health:

Pre-Storage Preparation

Begin by cleaning the battery casing and contacts with a dry cloth to remove any grass clippings, dirt, or moisture. Check the charge level and adjust it to the recommended storage level (typically 40-60%) using the manufacturer's charger. Fully charging before storage might seem logical but actually accelerates degradation, while storing completely drained can lead to irreversible damage.

Ongoing Maintenance During Storage

The Yarbo support forum recommends charging the battery for about 5-10 minutes at least once every three months during extended storage . This brief maintenance charging helps compensate for natural self-discharge and keeps the battery electronics active. During these check-ins, visually inspect for any signs of damage, swelling, or leakage.

Reactivation Procedure

When the mowing season approaches, don't simply install the stored battery and expect immediate optimal performance. Begin by giving the battery a full charge using the manufacturer's recommended charger. Allow the battery to reach room temperature if it has been stored in a cool location before charging. After charging, perform a test run to verify runtime and performance before relying on it for regular mowing.

Based on my professional experience with battery systems, I've found that customers who implement a consistent winter storage routine typically experience significantly better battery performance in subsequent seasons. The small time investment in proper storage practices pays dividends in extended battery lifespan and reliable spring startup.

Conclusion

Choosing the right battery for your robotic lawn mower requires careful consideration of safety features, temperature resilience, lifespan expectations, and proper storage practices. By understanding these key aspects and implementing the recommendations outlined above, you can maximize both performance and longevity of your investment. Remember that the right battery choices and proper maintenance practices work together to ensure your robotic mower remains a reliable lawn care companion for years to come.