How to Install Water Pipe for Robot Cleaner? Views: 14 Author: Site Editor Publish Time: 2025-06-17 Origin: Site

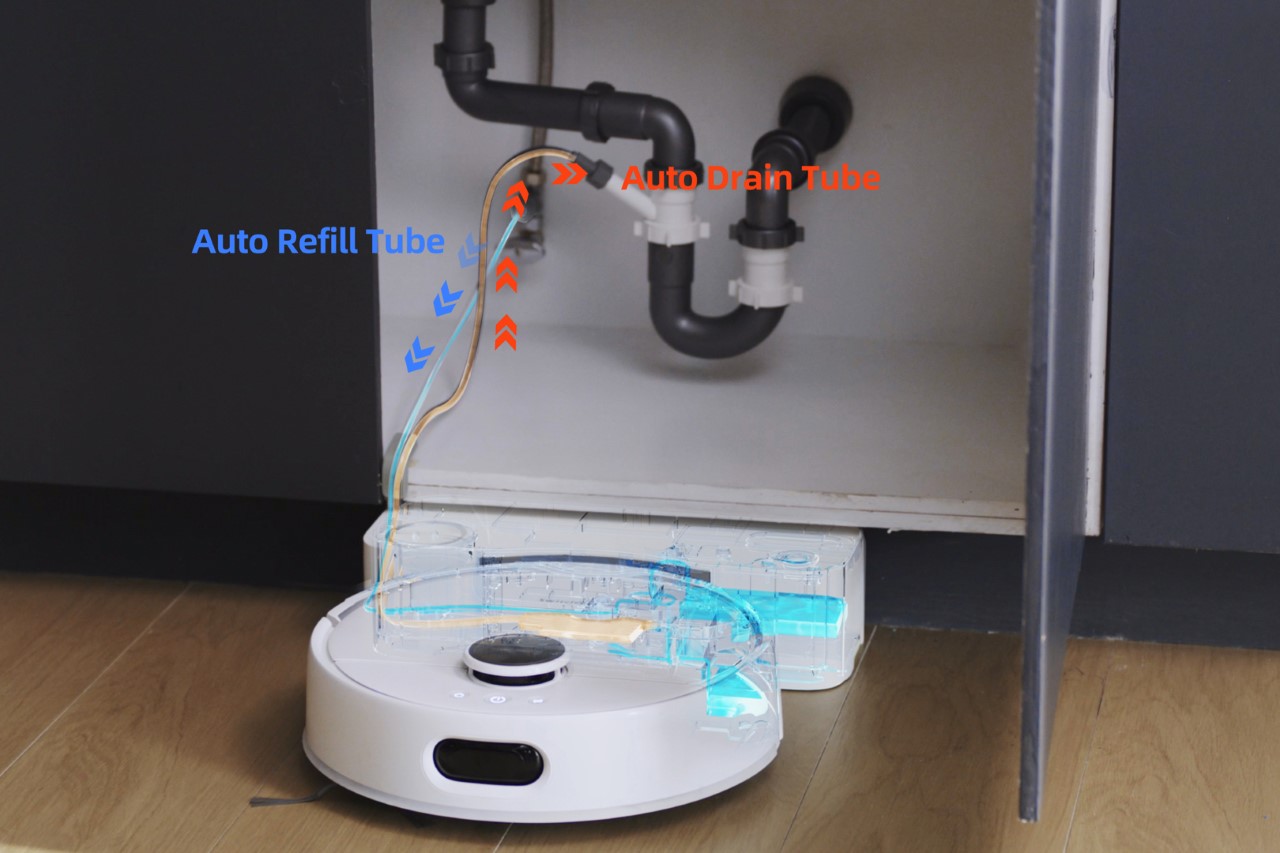

The Complete Guide to Installing Water Pipes for Robot Cleaners Robot cleaners

water connections. As a factory owner supplying robotic cleaners to 17 countries, I'll share professional installation techniques we recommend

to wholesalers and private-label partners.

Essential Tools and Materials for Professional-Grade Installation Tools Checklist:

Digital pressure gauge (0-100 PSI range)

Ratcheting PEX cutter (for clean 90° cuts)

Infrared thermometer (monitor pipe temperature)

Deburring tool (removes inner/outer pipe imperfections)

Torque wrench (for precise connector tightening)

Advanced Materials Table:

Material Purpose Recommended Specs PEX-AL-PEX Pipe

Main water line

1/2" diameter, oxygen barrier

Brass Compression Fittings

Connection points

Lead-free, WRAS approved

EPDM Rubber Seals

Leak prevention

5mm thickness, -40°C to 150°C range

Stainless Steel Clamps

Vibration resistance

304 grade, 12-20mm range

Pro Tip: For commercial installations, add a water hammer arrestor to protect the cleaner's pump from pressure surges.

Step-by-Step Professional Installation Process 1. Pre-Installation Planning Water Quality Test: Check for TDS < 50ppm and pH 6.5-8.0

Pressure Verification: Ensure 40-60 PSI static pressure

Route Mapping: Maintain ≤2 right-angle bends for optimal flow

2. Precision Pipe Preparation Measure with laser distance meter (add 10% for thermal expansion)

Cut using rotary pipe cutter (prevents oval deformation)

Deburr internal/external edges (reduces turbulence by 40%)

3. Military-Grade Connection System Apply thread sealant (Loctite 577 recommended)

Use two-clamp method at each joint

Torque fittings to 25-30 N∙m (use click-type wrench)

Case Study: A Canadian client reduced leaks by 92% after switching to this connection method.

Advanced Testing Protocol Three-Phase Quality Assurance:

Initial Pressure Test:

1.5x operating pressure for 30 minutes

Check for ≥0.5 PSI drop (indicates leaks)

Thermal Cycling:

Alternate between 5°C and 50°C water

5 complete cycles

Flow Verification:

Measure output at cleaner inlet (should be 1.8-2.2 GPM)

Check for laminar flow (no visible turbulence)

Maintenance Schedule for Commercial Installations Frequency Task Tools Needed Weekly

Visual inspection

Flashlight

Monthly

Seal lubrication

Food-grade silicone grease

Quarterly

Pipe descaling

Circulating pump, citric acid solution

Annually

Full pressure test

Digital gauge, log book

Note: In hard water areas (≥120 ppm), install a 5-micron pre-filter to prevent mineral buildup.

Troubleshooting Advanced Issues Problem: Intermittent water flow

Problem: Vibration noises

Problem: Early morning leaks

Conclusion: Professional Results Require Precision Proper water pipe installation extends your robot cleaner's lifespan by 3-5 years and maintains peak cleaning performance. For bulk buyers (50+ units), we provide:

Custom pipe kits with pre-measured lengths

Installation training videos

Technical support hotline